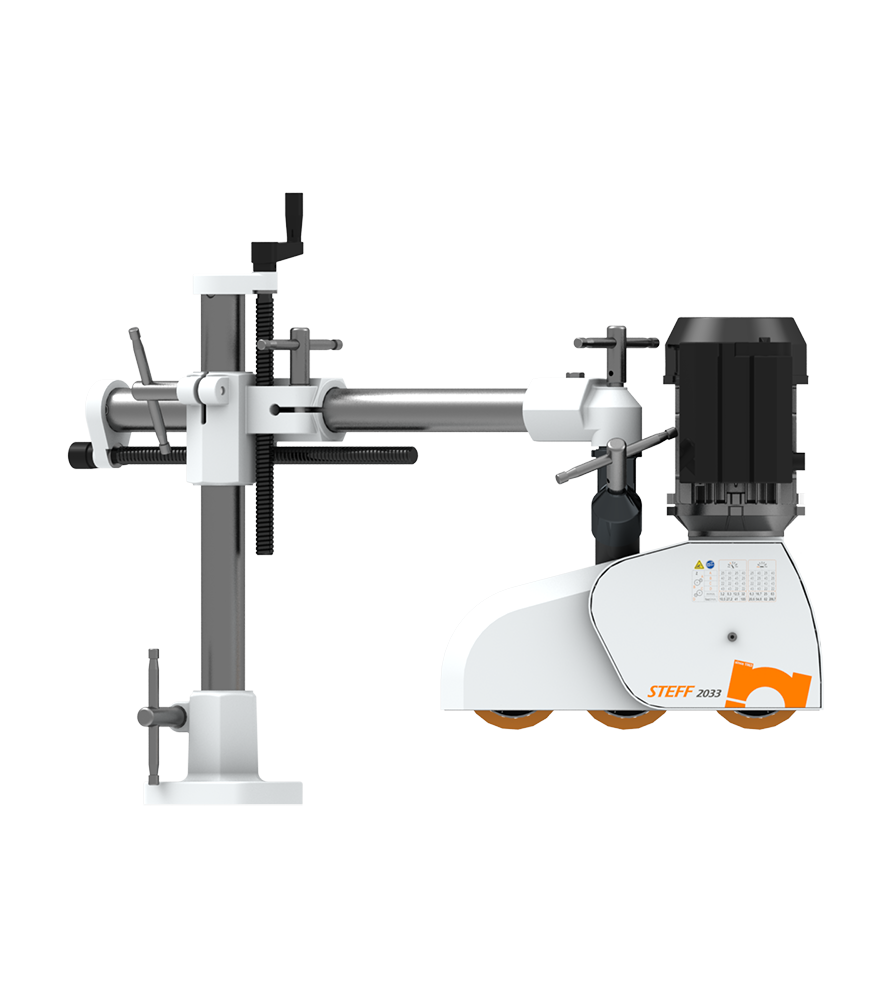

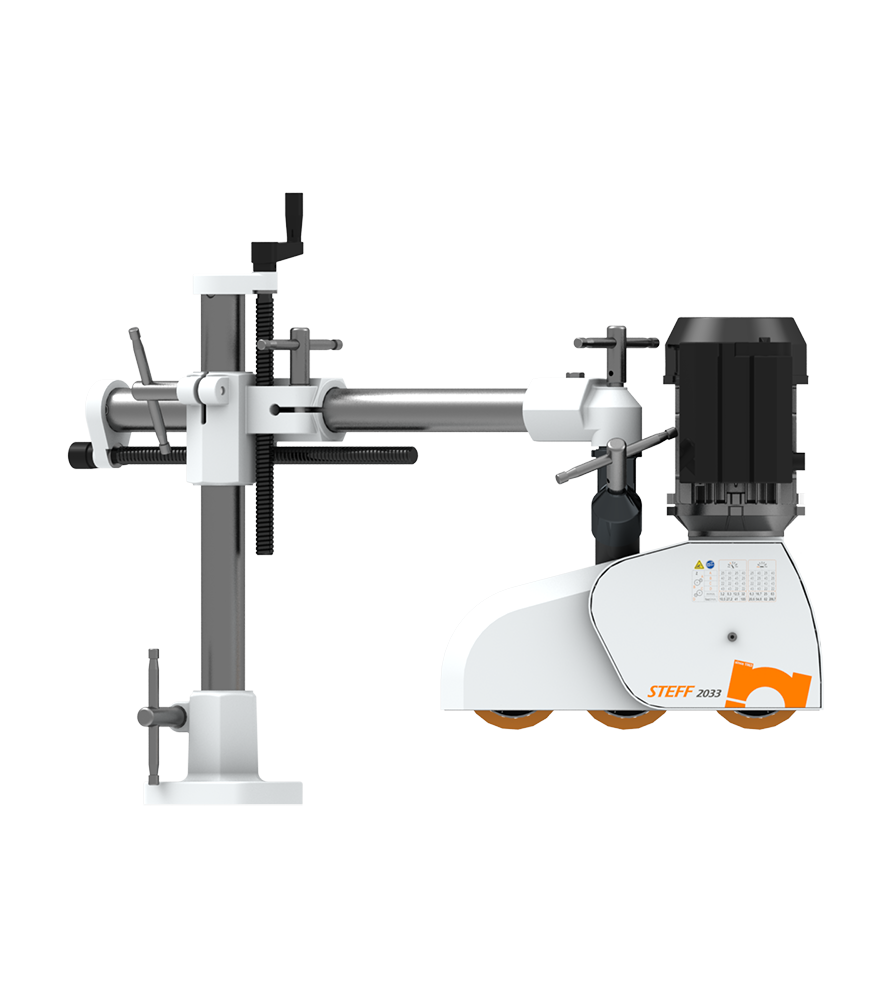

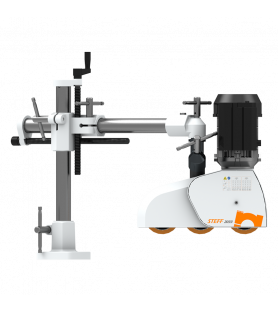

Double joint kit for STEFF2033 trainer

Double joint kit for STEFF2033 power feeder

Including €2.80 for ecotax

Reference: MSTEFF2033-230V

Automatic power feeder Maggi Steff 2033 for spindle moulder - 750W, semi-professional, with 8 fixed speeds

.png)

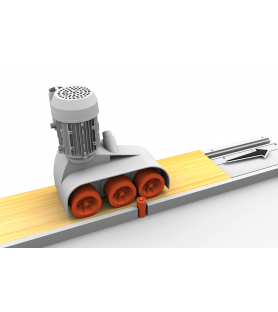

Accident prevention device to power conventional machines correctly and safely.

Work in complete safety: the operator does not bring his hands near the tool - Superior quality machining thanks to the constant advancement of the part - Optimal feeding thanks to speed adjustment - Adaptability to all machining requirements

60 years of experience with a production of more than 400,000 machines: 100% Italian products. Very high levels of quality and reliability, thanks to the “Lean” Toyota System manufacturing method.

QUALITY MACHINING

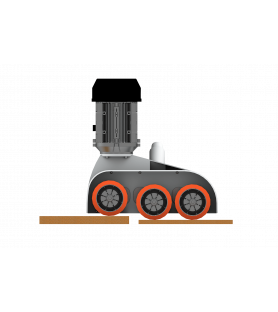

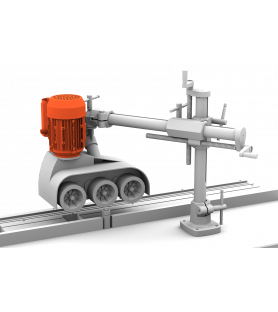

Model with 3 rollers, ideal for driving slats, small parts and for medium-sized machining, thanks to the 2 rollers which perfectly hold the part at the entrance and the roller which holds it at the exit.

QUICK ADJUSTMENT

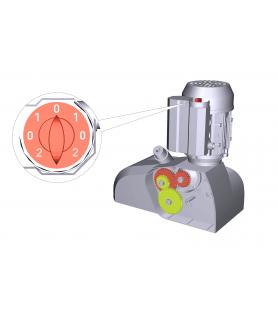

8 SMART SPEEDS

By reversing the gears, you double the number of speeds available. The selector on the motor also allows you to quickly change between speeds 1 and 2 and reverse the direction of travel.

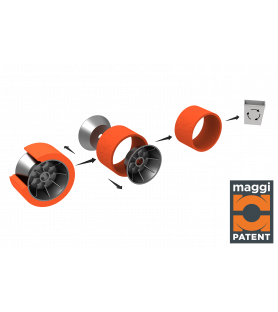

ECO PEBBLES

3 patented SHS System Feeder Grip 50 Shore rollers. Superior adhesion. Roller wear reduced by 51%. Thanks to the replaceable rubber coating, it produces less waste to better respect the environment.

THE VALUE OF SAFETY

Using automatic feed protects the operator's hands from serious accidents. Its effectiveness depends on precise design and manufacturing criteria. MAGGI trainers are the only ones designed and manufactured in Italy. They comply with all CE safety regulations.

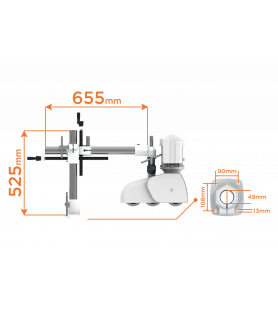

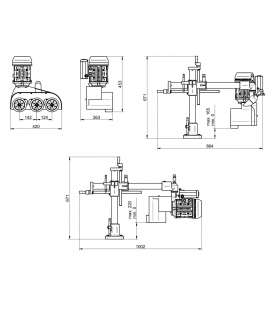

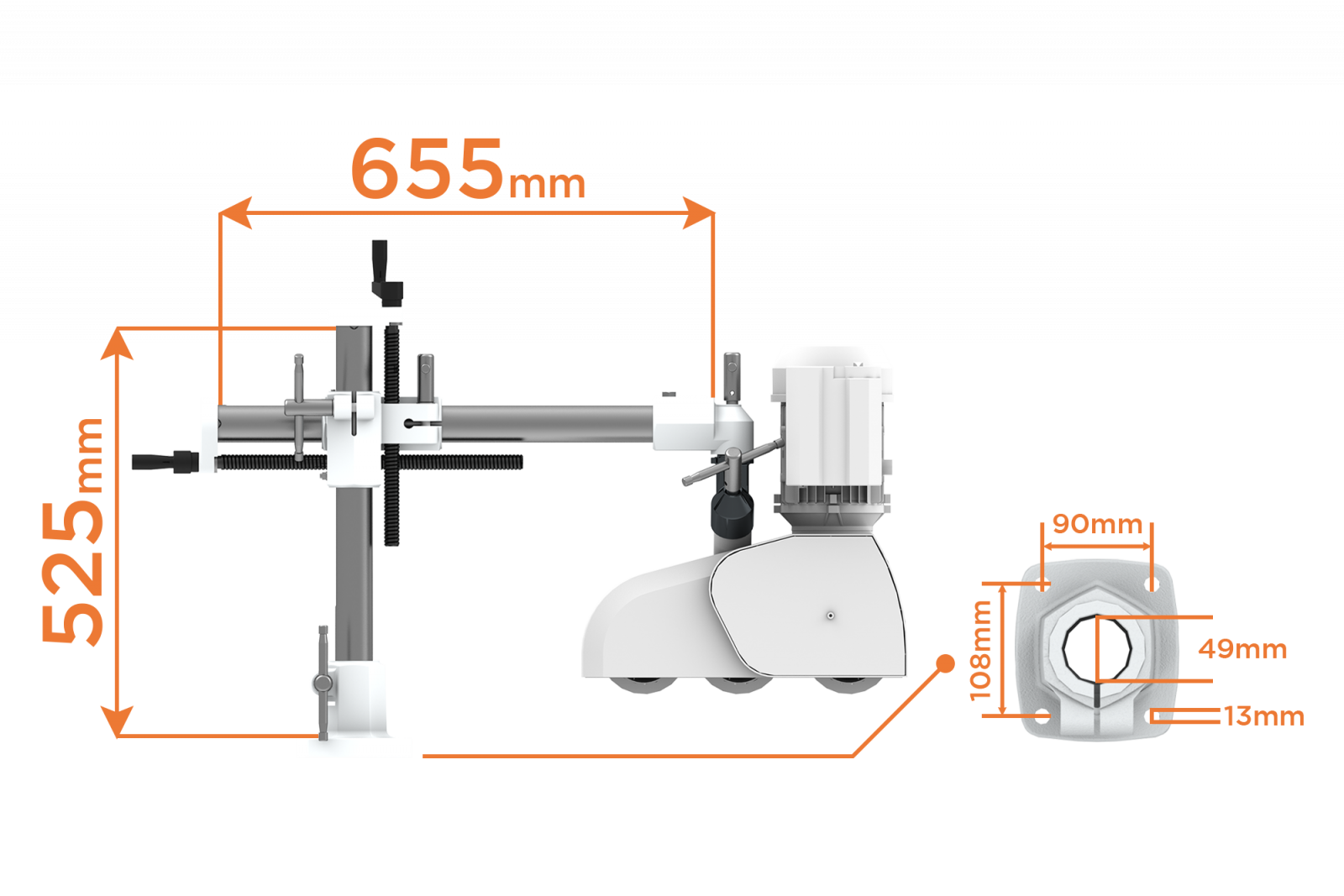

UNIVERSAL BRACKET

Structure for support and optimal positioning of the automatic feeder on the machine tool. Easy to orient, stable and robust; cast iron base, crosspiece, cap, pipe, and junction and two very thick ground steel columns. Adjustment keys and handwheels ensure rapid and precise positioning.

HIGH ADAPTABILITY

the well-calibrated spring suspension: 20 mm, allows parts with different thicknesses to be advanced without the need for additional adjustments

ZERO MAINTENANCE AND LUBRICATION

The transmission system on ball bearings greatly reduces wear and friction, allowing considerable energy savings. Unique on the market

SMALL BUT POWERFUL

Equipped with a 0.7 kW motor and produced using the same materials and the same technical precautions as for the manufacture of professional models. Thanks to its reduced size, this trainer can work, while always ensuring optimal performance, with semi-professional machine tools.

STRONG AND RELIABLE SUPPORT

Equipped with an anti-stall mechanical safety device "SPS System" which prevents any accidental disconnection of the elements, in compliance with CE safety standards.

Double joint kit for STEFF2033 power feeder

Tilting plate Maggi ref 22100151 for use with a large power feeder