Including €2.80 for ecotax

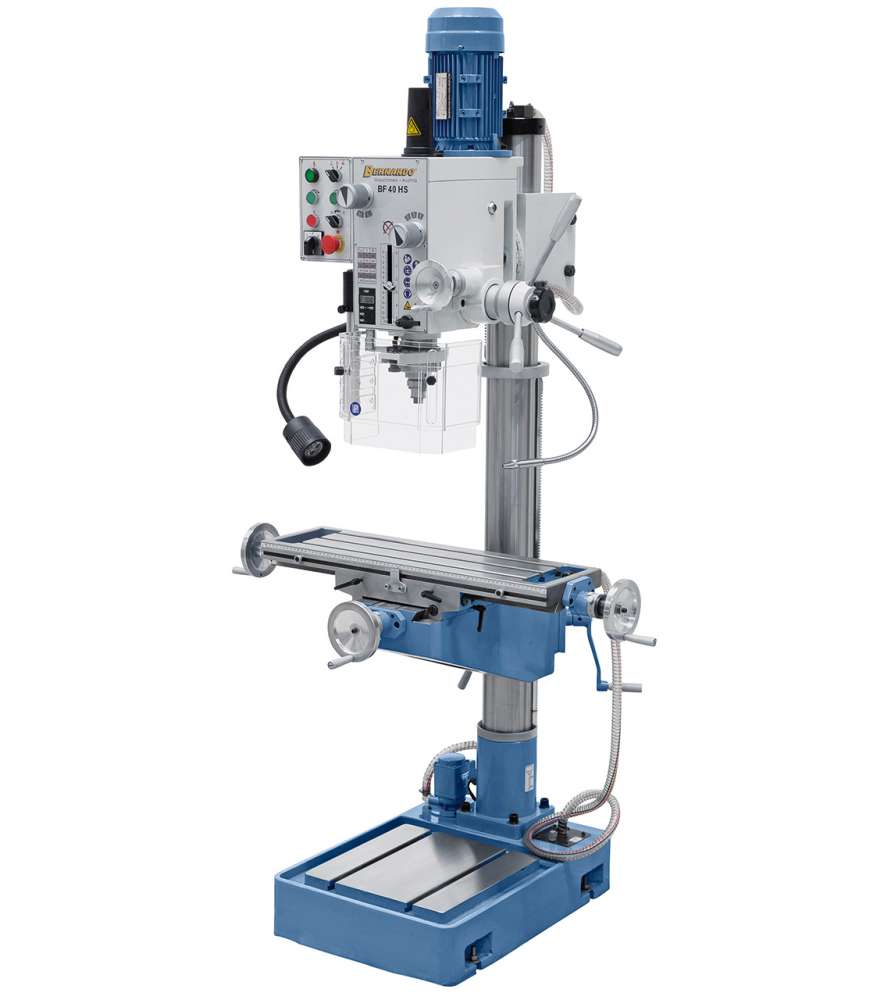

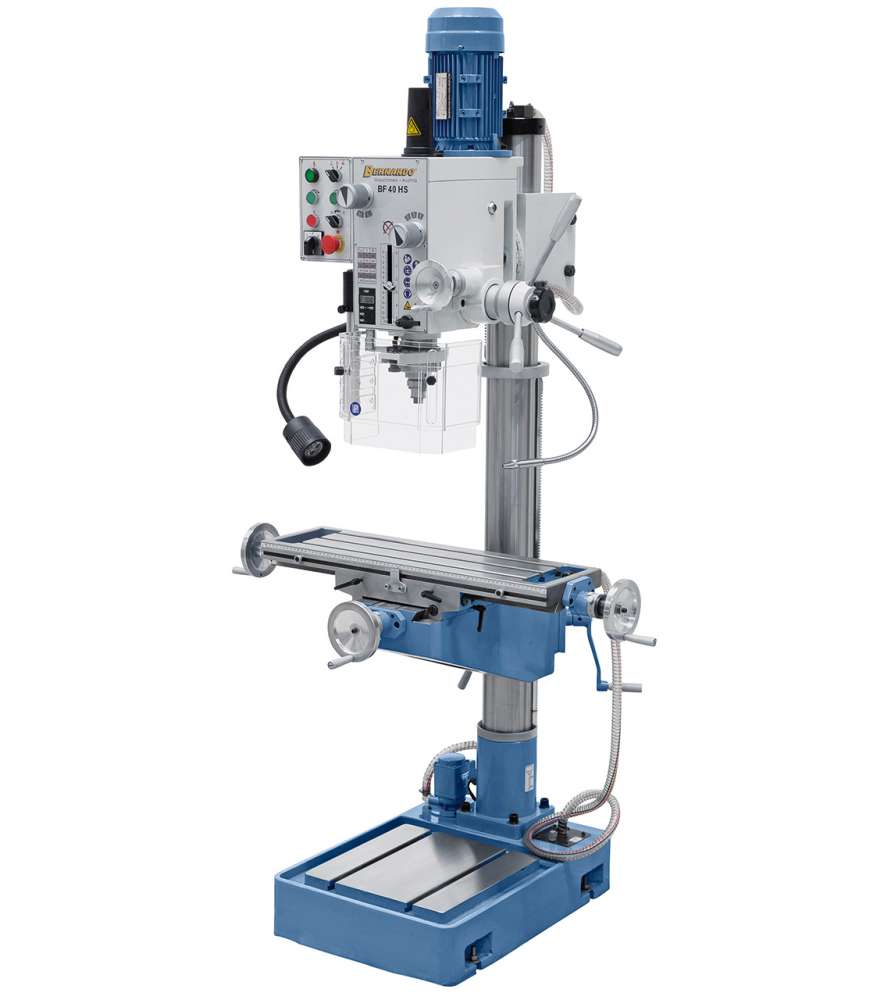

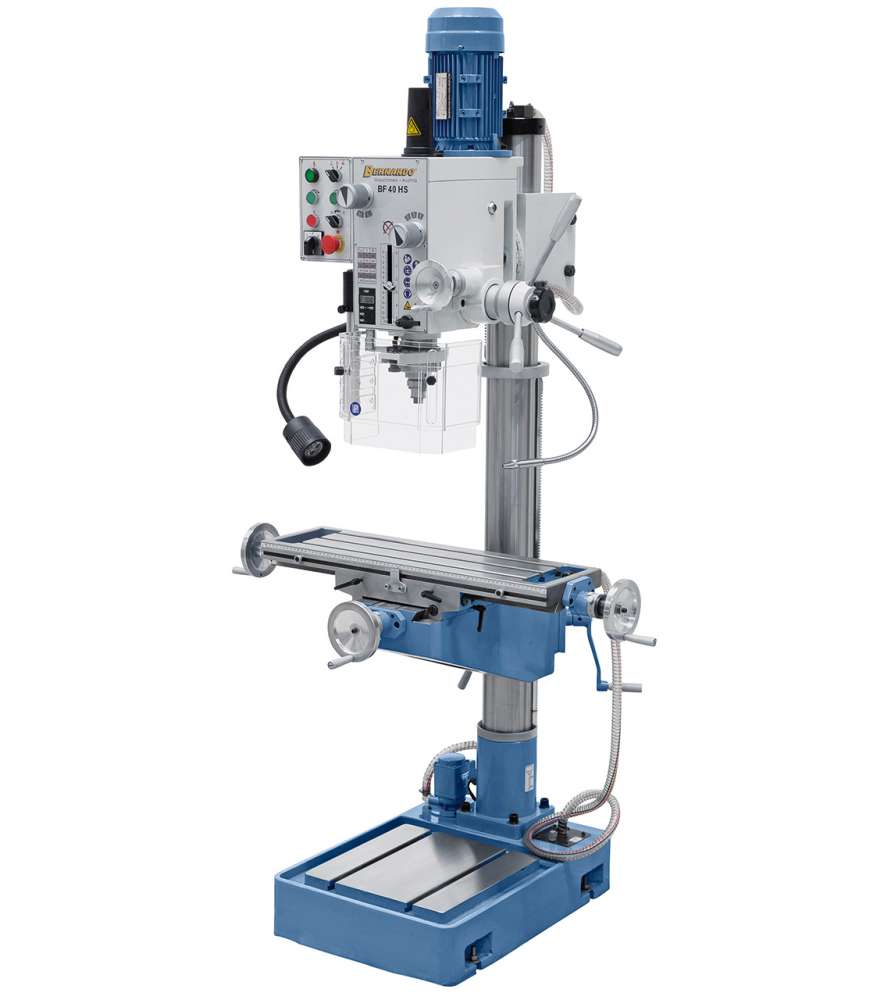

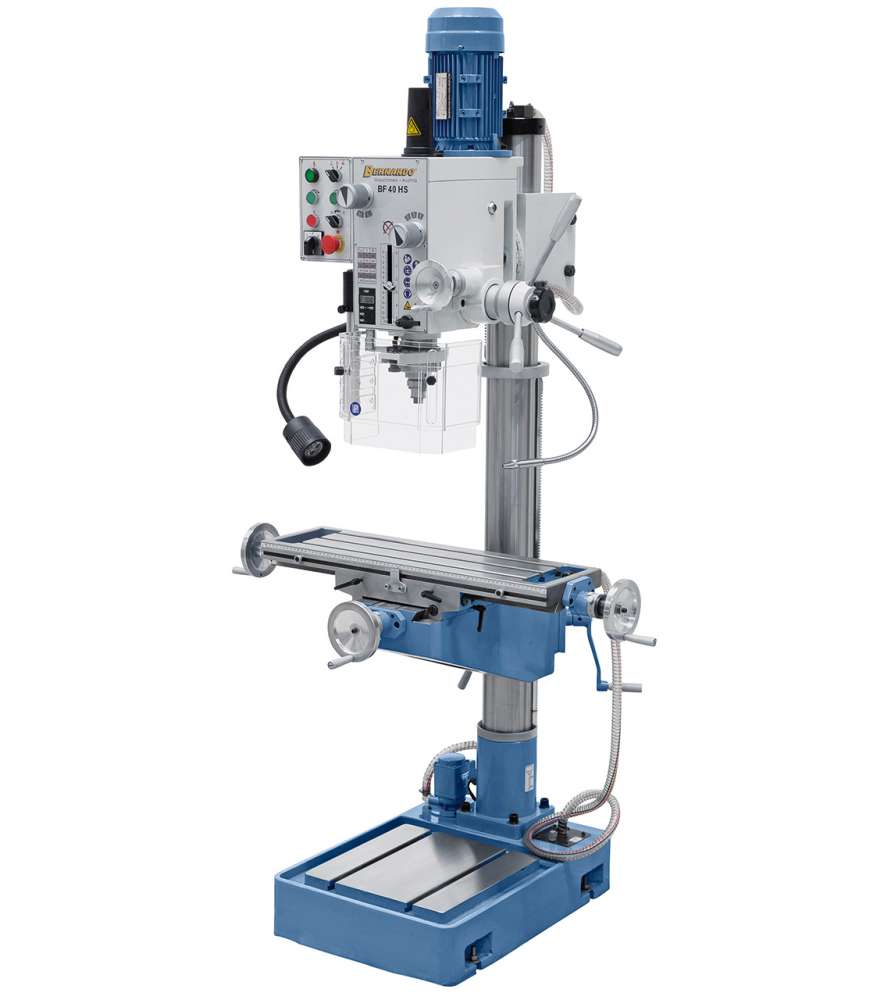

Reference: BF40HS

The Bernardo BF40HS precision milling drill is ideal for drilling, milling and various machining tasks. With its swivel and tilting head, it is ideal for repair, training and general mechanics workshops.

.png)

The Bernardo BF40HS precision milling drill is ideal for drilling, milling and various machining tasks. With its swivel and tilting head, it is ideal for repair, training and general mechanics workshops.